Elin Turbomaschinen Solutions

Elin Turbomaschinen GmbH designs and manufactures advanced Dry Gas Seals (DGS) for centrifugal compressors, turboexpanders, and critical rotating equipment in the oil, gas, and petrochemical sectors. Our seals are built to API 692 and ISO 10439 standards , supporting both OEM replacements and retrofit upgrades for compressors operating under demanding conditions.

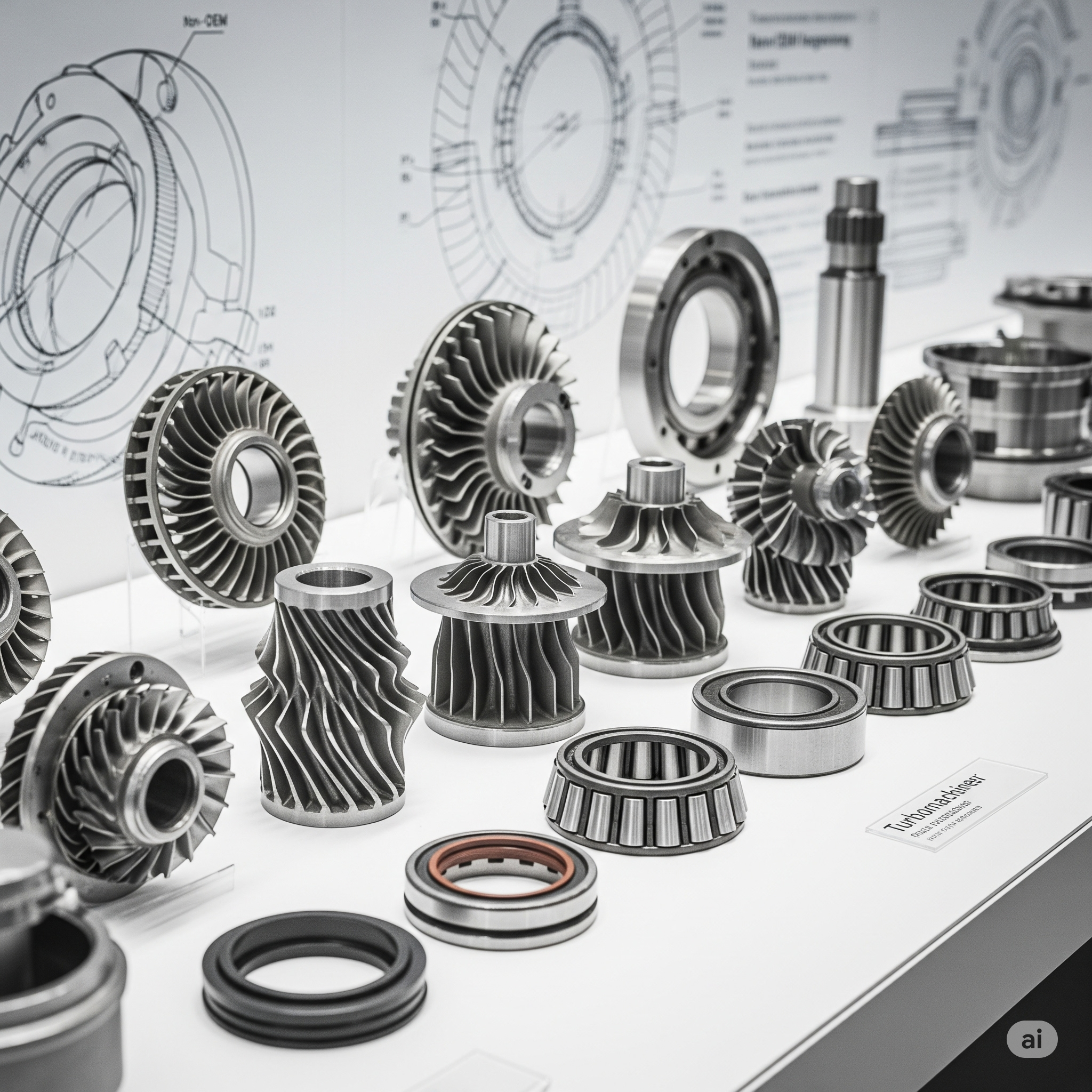

Seal Types & Capabilities

Our seals are engineered to meet specific operational needs:

- Configurations: Single, Tandem, Tandem with Intermediate Labyrinth (Tandem-L), and Double-Pressurized configurations.

- Compatibility: Compatible with sour gas, hydrogen, CO2, and high-pressure/high-speed services.

- Technical Specs: Shaft diameters up to 400+ mm, speeds up to 35,000 rpm, and pressures up to 200 bar.

Advanced Materials

We use superior materials for extreme performance:

- Seal Faces: We use reaction bonded and hot pressed Silicon Carbide (RB-SIC, HP-SIC) for wear and thermal resistance. Resin-impregnated carbon graphite is used for stability in dry-run cycles, and DLC-coated seal faces for reduced friction and heat protection.

- Elastomers: Our elastomers include FFKM, Viton® Extreme, and Kalrez® for chemically aggressive services. All materials undergo compatibility and lifecycle validation for each application.

Manufacturing & Testing Excellence

All our seals are designed, machined, and assembled in-house with micron-level precision. Our test facilities enable:

- Live Testing: Static & dynamic testing with live monitoring of leakage, face temperature, and vibration.

- Simulation & Validation: Pressure cycling, dry run simulations, and gas compatibility validation.

- Certification: Full FAT documentation and compliance certification (API/ISO).

Advanced Retrofit Solutions & Root-Cause Design Engineering

At Elin, retrofitting is not just component replacement—it’s an engineering-led problem-solving process. We analyze failure history, process dynamics, and seal conditions, then apply CFD and precision design tools to engineer tailored sealing solutions.

- Diagnostics: Root cause diagnostics and reengineering of failed seals.

- Redesign: DGS redesign for harsh conditions and legacy compressors.

- Retrofit-Ready: Our solutions are retrofit-ready with form-fit-function equivalence and optional housing upgrades.

Spare Parts Coverage (Non-OEM Equivalent)

View project

Field Services & Engineering Support

View projectReverse Engineering & Field Support

We deliver non-OEM seal solutions equivalent to brands like John Crane, EagleBurgmann, and Flowserve. Our services are supported by:

- Technical Analysis: 3D scanning, material analysis, and CAD/CAM design.

- On-site Support: Installation & troubleshooting in Europe and the Gulf region.

- Emergency Service: Emergency rebuilds within 72 hours.

Real-World Application Example

- Case: Tandem-L DGS retrofit on a sour gas booster compressor (24-inch shaft).

- Outcome: Reduced methane leakage by 85%, restored seal lifecycle to 4+ years, and eliminated immigration risks.

Our seals are not just mechanical components—they are engineered safeguards for critical equipment and the environment.