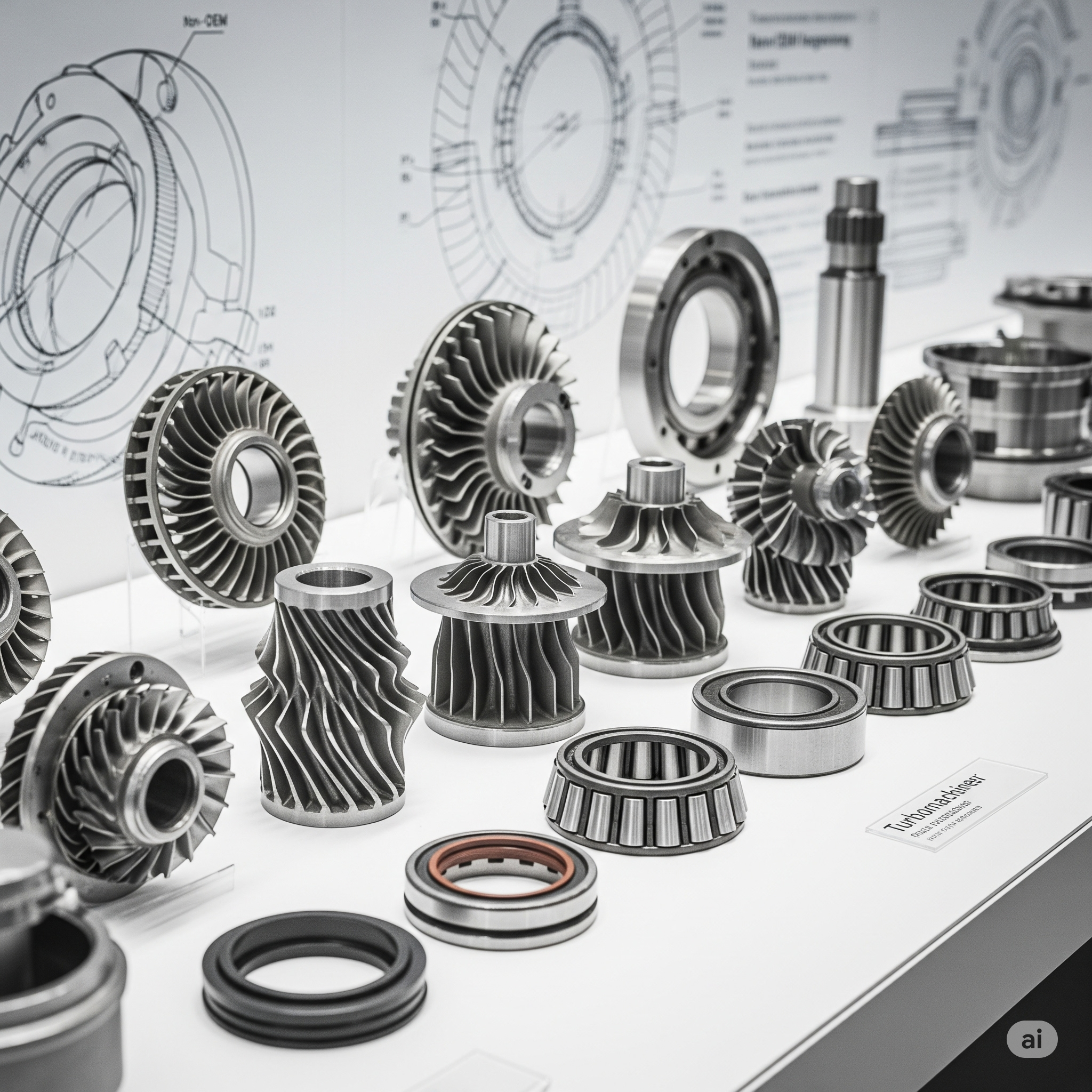

Elin Turbomaschinen Solutions

Elin Turbomaschinen GmbH designs and manufactures precision mechanical seals for rotating equipment operating under extreme chemical, thermal, and pressure conditions. Our seals serve critical functions in chemical processing, oil refining, power generation, and pharmaceutical industries, where standard seals fail to ensure integrity and uptime.

Seal Configurations & Applications

-

Configurations: Our portfolio includes Single, Double, Tandem, and Split Seals for horizontal/vertical pumps, agitators, and compressors.

-

Applications: Our seals are engineered for aggressive acids, slurries, flashing hydrocarbons, and high-purity fluids.

-

Compliance: Designs are compliant with API 682, ISO 21049, and DIN 24960.

-

Operating Range: Our seals can withstand pressures up to 100 bar and temperatures from -70°C to +450°C.

Materials & Surface Technologies

We utilize high-performance materials and advanced surface technologies:

-

Seal Faces: Our seal faces use hot-pressed Silicon Carbide (SiC), Tungsten Carbide, antimony graphite, and DLC coatings.

-

Elastomers: We use elastomers like Chemraz®, Kalrez®, and AFLAS® for extreme chemical and thermal resistance.

-

Validation: All materials are selected based on tribological modeling and validated through long-term lifecycle testing.

Spare Parts Coverage (Non-OEM Equivalent)

View project

Field Services & Engineering Support

View projectDesign Specialties & Custom Capabilities

Our engineering team specializes in custom solutions for unique challenges:

-

Gas-lift seals for flashing fluids.

-

Edge-welded metal bellows for cryogenic and viscous media.

-

Non-pusher and split designs for retrofit and restricted spaces.

-

Integrated flush plans and barrier systems (Plan 32, Plan 53A/B/C).

Independent Design – Evolved Beyond OEM Standards

At Elin, we do not simply replicate OEM designs—we engineer our own seal solutions that address known limitations found in legacy or mainstream brands. Our design process leverages:

-

Field experience and failure diagnostics.

-

CFD-assisted flow and distortion modeling.

-

Custom geometries that prevent hang-up, coking, and thermal shock.

Our seals remain dimensionally compatible but offer improved lifecycle, stability, and chemical tolerance under real-world stress.